Capabilities

Engineering

- In-house facilities for design in accordance with Indian & International Codes & Standards.

- In-house Design facility using licensed copy of PV Elite Integrated Design Software, Evaluation & Mechanical Design For Pressure Vessels, Columns as per ASME Sec. VIII Div. I & PD 5500. Finite Element Analysis using Nozzle Pro.

- CODECAL (Design & Analysis Software) For Heat Exchangers & Components as per TEMA & ASME standards.

- THERMAL DESIGN – along with associates in the field for Thermal Design on case-to-case basis using HTRI software.

In-house facilities for preparation of all Fabrication Drawings, Plot Design. (ACAD) and as per ASME standards. - All ASME codebooks are available.

Manufacturing

With a manufacturing footprint reaching across globe, RAJ Engineering Co. is positioned to meet demanding production schedules with expedited delivery in an economical manner. We use latest design tools to fabricate with the strictest standard and client specifications.

Welding & Metallurgies

Quality

ISO 9001:2015, 14001:2015, 45001:2018 & ASME ‘U’ ‘U2’ ‘S’ ‘R’ STAMP CERTIFIED CO.

Quality

ISO 9001:2015, 14001:2015, 45001:2018 & ASME ‘U’ ‘U2’ ‘S’ ‘R’ STAMP CERTIFIED CO.

- Engineering

- Manufacturing

- Welding & Metallurgies

- Quality

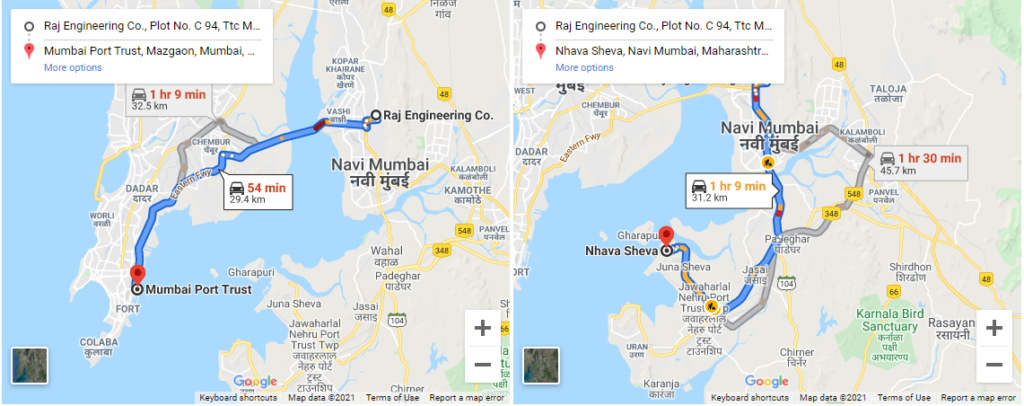

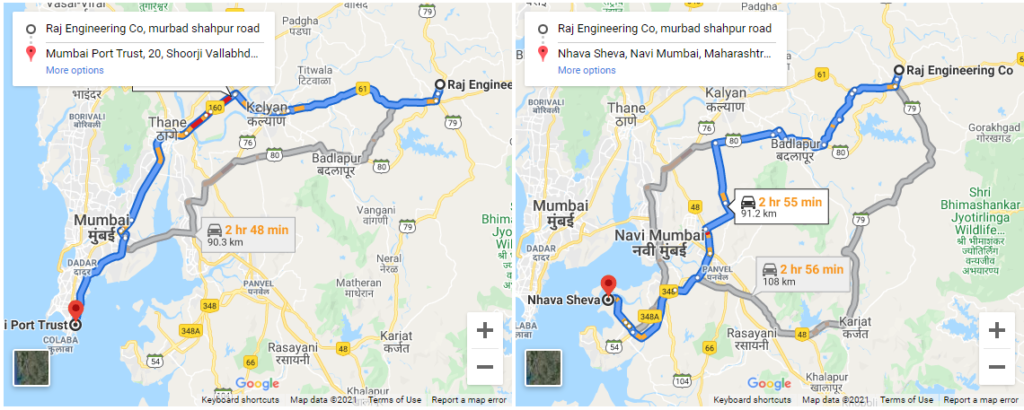

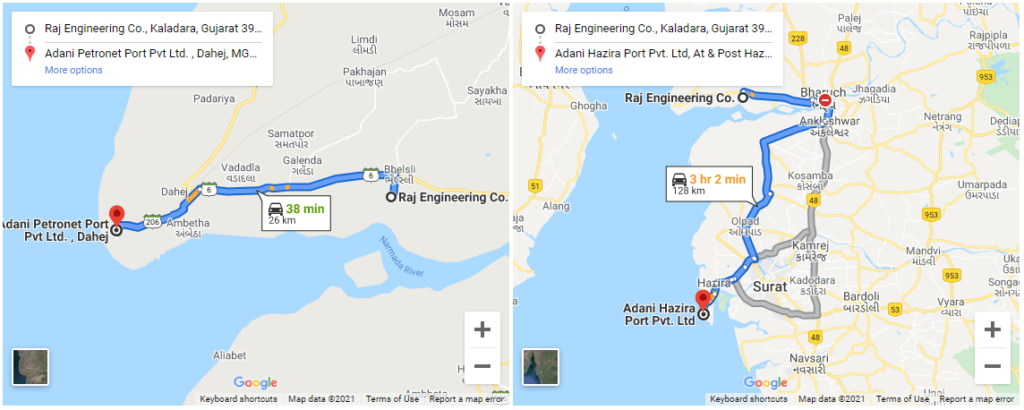

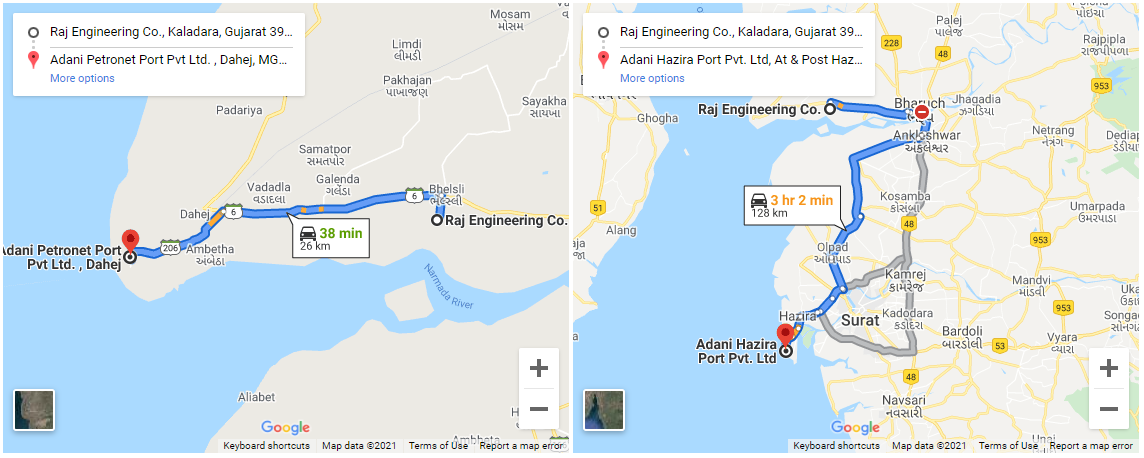

- Logistics

Engineering

- In-house facilities for design in accordance with Indian & International Codes & Standards.

- In-house Design facility using licensed copy of PV Elite Integrated Design Software, Evaluation & Mechanical Design For Pressure Vessels, Columns as per ASME Sec. VIII Div. I & PD 5500. Finite Element Analysis using Nozzle Pro.

- CODECAL (Design & Analysis Software) For Heat Exchangers & Components as per TEMA & ASME standards.

- THERMAL DESIGN – along with associates in the field for Thermal Design on case-to-case basis using HTRI software.

In-house facilities for preparation of all Fabrication Drawings, Plot Design. (ACAD) and as per ASME standards. - All ASME codebooks are available.

Manufacturing

With a manufacturing footprint reaching across globe, RAJ Engineering Co. is positioned to meet demanding production schedules with expedited delivery in an economical manner. We use latest design tools to fabricate with the strictest standard and client specifications.

Welding & Metallurgies

Quality

ISO 9001:2015, 14001:2015, 45001:2018 & ASME ‘U’ ‘U2’ ‘S’ ‘R’ STAMP CERTIFIED CO.

Quality

ISO 9001:2015, 14001:2015, 45001:2018 & ASME ‘U’ ‘U2’ ‘S’ ‘R’ STAMP CERTIFIED CO.